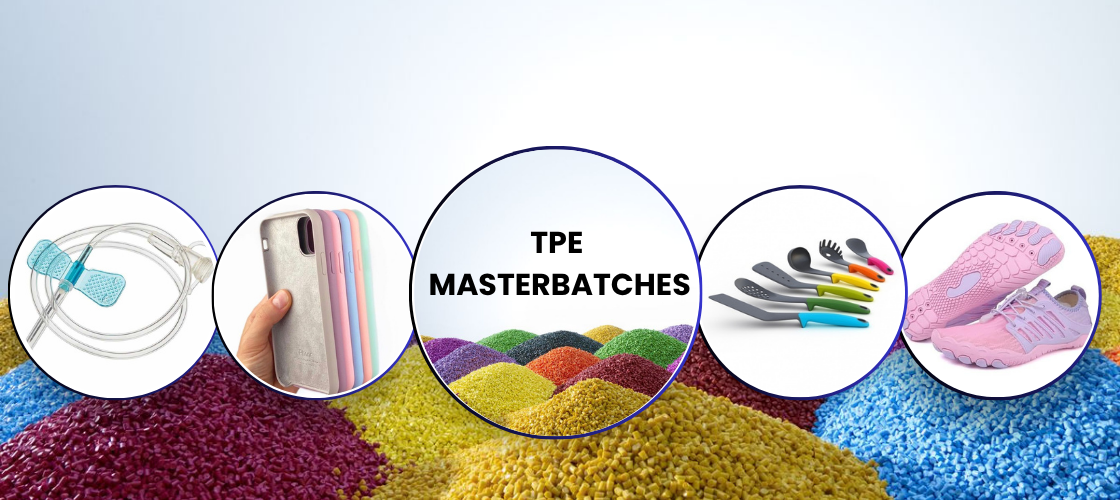

TPE MASTERBATCH

At Surya Compounds & Masterbatches, we offer a versatile range of TPE (Thermoplastic Elastomer) masterbatches designed for flexible and high-performance applications. Our TPE Masterbatches include Color, Black, and Functional grades engineered for excellent dispersion, consistent shade stability, and smooth processing. These masterbatches enhance flexibility, elasticity, and abrasion resistance while maintaining TPE’s soft-touch feel and durability. Ideal for applications such as automotive seals, footwear, cable insulation, and consumer goods, our TPE Masterbatches deliver reliable performance, superior aesthetics, and long-term stability.

Key Features of Surya’s TPE Masterbatches

- Excellent dispersion for uniform color and performance

- Consistent shade stability across batches

- Enhanced flexibility and elasticity

- Improved abrasion and wear resistance

- Superior soft-touch feel and durability

- Optimal compatibility with TPE resins

- Smooth processing in extrusion and molding

- Low plate-out and clean processing behavior

- High-quality raw materials for reliable performance

- Suitable for automotive seals, footwear, cables, and consumer goods

Applications of TPE Masterbatch

Our TPE Masterbatch is widely used in applications requiring soft-touch, grip, or flexible parts.

Common applications include:

- Automotive interiors and seals

- Cable insulation and grips

- Footwear soles and straps

- Household appliances and tool handles

- Medical tubing and sports goods

The versatility of TPE masterbatch allows manufacturers to achieve optimal performance while maintaining cost-efficiency and ease of production.

Why Choose Surya Compound & Masterbatches

- Customized Formulations: Designed according to your polymer base and processing method.

- Advanced Technology: State-of-the-art manufacturing facilities for precision output.

- Fast Delivery: Efficient production and logistics for on-time delivery.

- Technical Support: Dedicated experts to guide you from product selection to implementation.

We focus on sustainable, cost-effective, and high-performance masterbatch solutions that enhance your end product quality.

Get in Touch

If you’re looking for a reliable TPE Masterbatch manufacturer to enhance your product quality, contact Surya Compounds & Masterbatches today.

FAQ

What is a TPE masterbatch used for?

A TPE masterbatch is used to modify the flexibility, texture, and performance of thermoplastic elastomer materials in various applications like automotive parts, footwear, and cables.

What industries use TPE masterbatch the most?

Industries such as automotive, construction, medical, packaging, and consumer goods use TPE masterbatch for its elasticity and durable characteristics.

How do I choose the right TPE masterbatch for my product?

You should consider factors like the polymer base, desired color, mechanical strength, and processing method. Our experts at Surya Compounds & Masterbatches can help you select the right formulation.

Are TPE masterbatches eco-friendly?

Yes, our TPE masterbatches are designed with recyclable and non-toxic materials, ensuring minimal environmental impact.

What makes Surya Compounds & Masterbatches a reliable TPE masterbatch supplier?

Our commitment to quality, customization, and continuous innovation makes us one of the most trusted TPE masterbatch manufacturers and suppliers in the industry.