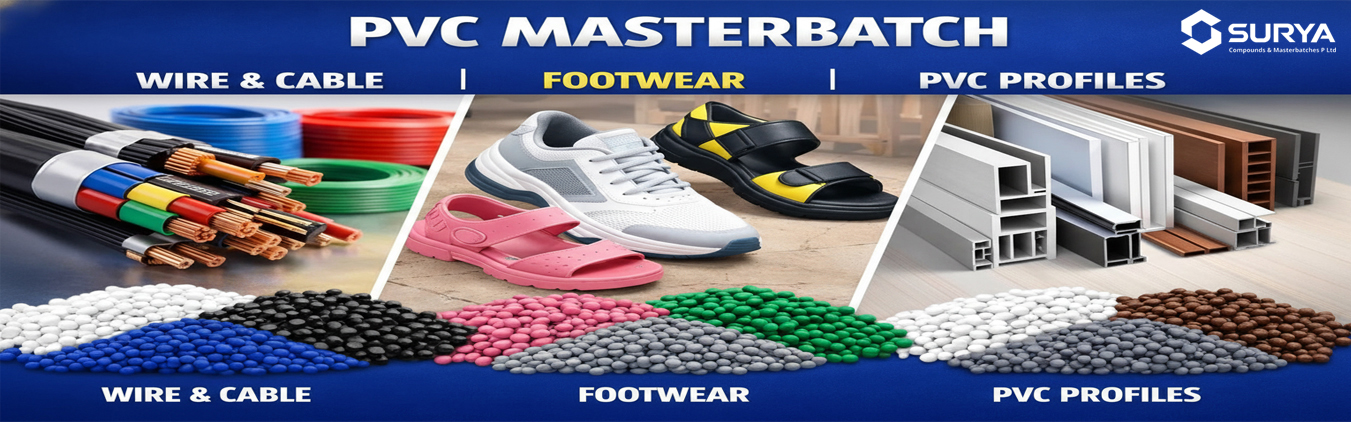

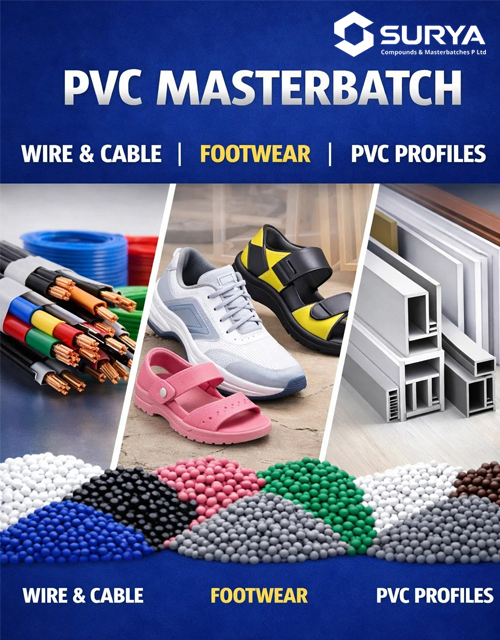

PVC MASTERBATCH

We, at Surya Compounds & Masterbatches, offer a comprehensive range of PVC Masterbatches designed to meet diverse industry needs. Our products include color masterbatches for vibrant and consistent pigmentation, white masterbatches for high-opacity and clean finishes, and black masterbatches for UV stability and superior coverage. We also manufacture functional masterbatches such as UV stabilizers etc., ensuring enhanced processing performance and long-term durability. All our PVC Masterbatches are formulated with high-quality raw materials, ensuring excellent dispersion, uniformity, and reliable performance in applications like cables, pipes, profiles, medical tubes, flooring and many more.

Key Features of Surya’s PVC Masterbatches:

As a leading PVC masterbatch manufacturer, we use advanced technology and strict quality control at every stage of production. Our in-house team of experts ensures that every masterbatch formulation delivers:

- Excellent color dispersion for uniform and consistent appearance

- Superior processing stability for smooth extrusion and molding

- High heat stability ensuring minimal degradation during processing

- Optimal compatibility with PVC resins for easy blending

- Enhanced UV resistance for long-term outdoor performance

- Improved mechanical strength for durable end products

- Reduced processing defects and waste

- Available in specialized formulations including flame retardant and functional masterbatches

- Consistent quality as we are using high-grade raw materials

When you partner with Surya Compounds & Masterbatches, you receive innovative solutions tailored to your specific application requirements.

Applications of PVC Masterbatch

Our PVC masterbatch is widely used across multiple industries, making it one of the most versatile additives for PVC products. Some common applications include:

- Pipes and fittings: For improved strength and appearance

- Electrical cables: For insulation, flexibility, and flame retardancy

- PVC sheets and films: For enhanced gloss and color consistency

- Profiles and moldings: For durability and UV protection

- Footwear and household items: For bright color and smooth finish

Whether you need standard white, black, or custom color PVC masterbatch, we have a solution designed for your exact need.

Customized PVC Masterbatch Solutions

As trusted PVC masterbatch suppliers, we understand that each application is unique. That’s why we offer custom-developed masterbatches to meet your production goals. Our R&D team works closely with clients to develop formulations that ensure:

- Optimal color accuracy

- Faster processing time

- Improved product stability

- Reduced wastage and downtime

Our customized approach helps businesses stay competitive and maintain product consistency in every batch.

Why Our Clients Prefer Surya Compounds & Masterbatches

- Over a decade of experience in the masterbatch industry

- Reliable delivery and consistent batch quality

- Dedicated customer support for technical queries

- Environmentally responsible manufacturing practices

If you are looking for trusted PVC masterbatch manufacturers and suppliers in India, Surya Compounds & Masterbatches is your go-to partner.

FAQ

What is the main purpose of using PVC Masterbatch?

PVC masterbatch is used to add color and performance-enhancing additives to PVC products. It ensures uniform color dispersion, better UV protection, and improved mechanical strength.

Can I use PVC Masterbatch for both rigid and flexible PVC applications?

Yes, our PVC masterbatches are compatible with both rigid and flexible PVC materials. We customize formulations according to your specific product type and processing method.

How do I select the right PVC Masterbatch for my application?

Our technical team helps you choose the ideal masterbatch based on your required color, processing temperature, and final product performance needs.

What are the advantages of buying from Surya Compounds & Masterbatches?

We provide consistent quality, customized color matching, fast delivery, and expert technical support — all at competitive prices.

Do you supply PVC Masterbatch in bulk quantities?

Yes, as one of the leading PVC masterbatch suppliers, we offer bulk and customized packaging options to suit various production scales.