PP MASTERBATCH

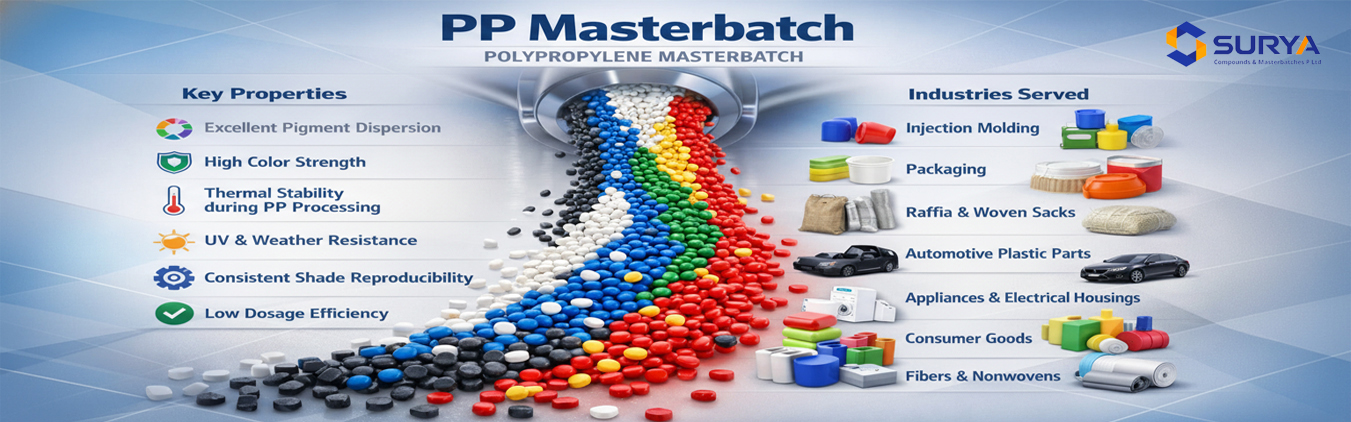

At Surya Compounds & Masterbatches, we offer a comprehensive range of PP masterbatches developed to meet the requirements of diverse industries and applications. Our portfolio includes Color, White, Black, and Additive Masterbatches designed for excellent dispersion, consistent color strength, and smooth processing. These PP Masterbatches enhance product appearance, UV resistance, heat stability, and mechanical performance. They are widely used in applications such as injection molding, raffia, fibers, films, automotive components, household products, and packaging. Manufactured using high-quality polypropylene carriers and additives, our PP Masterbatches ensure reliable performance, durability, and compliance with industry standards.

Key Points:

Improves color dispersion and surface finish in polypropylene materials.

Enhances UV stability, heat resistance, and mechanical properties.

Reduces processing costs by ensuring uniform mixing.

Offers customization for specific industrial applications.

Ensures long-lasting, high-quality end products for packaging, automotive, and household goods.

Surya Compounds & Masterbatches delivers high-performance PP masterbatch solutions trusted by manufacturers nationwide.

Importance of PP Masterbatch

PP Masterbatch plays a vital role in enhancing the quality and performance of polypropylene products. It provides consistent color, strength, and durability, ensuring superior output across industries.

Applications of PP Masterbatch

- Injection-molded products

- Woven sacks and non-woven fabric

- Plastic films and packaging

- Automotive parts and trims

- Household and consumer products

Our polypropylene masterbatch enhances the final product’s aesthetic appeal, durability, and UV stability, thereby extending its life and visual quality.

Key Features of Surya’s PP Masterbatches

- Excellent dispersion ensuring uniform color and consistent performance

- High color strength with excellent shade reproducibility

- Superior processing stability for smooth molding and extrusion

- Good heat and thermal stability during processing

- Enhanced UV resistance for long-term durability

- Improved mechanical properties such as strength and impact resistance

- Optimal compatibility with PP resins

- Low dosing requirement for cost-effective usage

- Available in the colors white and black and in functional grades

- Suitable for injection molding, fibers, raffia, films, automotive, and packaging applications

Why Choose Surya Compounds & Masterbatches for PP Masterbatch

We combine innovation and technology to create PP Masterbatch that ensures maximum performance. Our masterbatches are tested under strict quality control to maintain color accuracy, heat stability, and strength.

As a reliable PP masterbatch supplier, Surya Compound & Masterbatches offer both standard and customized solutions to meet client-specific color and performance requirements

FAQ

What is PP Masterbatch used for?

PP Masterbatch is used to add color, strength, and UV protection to polypropylene-based plastic products. It enhances the final appearance and durability of each item.

Can PP Masterbatch be customized?

Yes, we offer fully customized formulations based on your color, finish, and application requirements. Our experts create masterbatches to suit your exact specifications.

Which industries use PP Masterbatch?

PP Masterbatch is widely used in packaging, automotive, textiles, and household goods manufacturing. It helps improve both the look and performance of plastic materials.

Does it improve UV stability?

Yes, our PP Masterbatch includes UV stabilizers that protect plastics from sunlight damage. It’s ideal for outdoor and long-term exposure products.

How does PP Masterbatch help in manufacturing?

It ensures consistent color, reduces processing defects, and improves production efficiency for PP products.