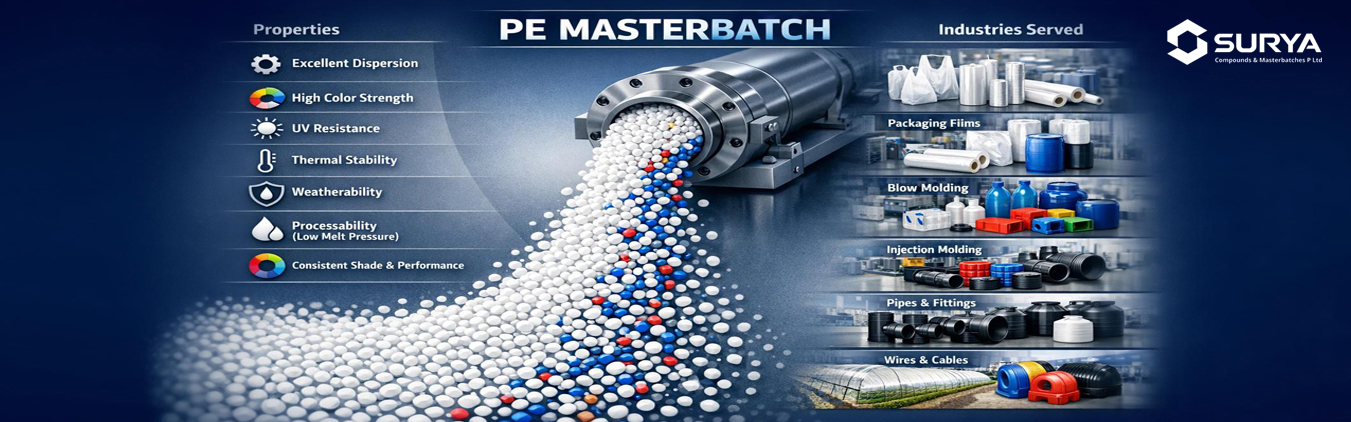

PE MASTERBATCH

At Surya Compounds & Masterbatches, we produce a wide range of PE Masterbatches designed to serve multiple industries and applications. Our portfolio includes Color, White, Black, and Additive Masterbatches engineered for excellent dispersion, consistent performance, and easy processing. These PE masterbatches enhance product aesthetics, UV resistance, mechanical strength, and processing efficiency. They are suitable for applications such as Films, Packaging, Pipes, Cables, Blow molding, Injection molding, and Extrusion. Formulated using high-quality polymers and additives, our PE masterbatches ensure reliable performance, durability, and compliance with industry standards, helping customers achieve superior product quality across diverse end-use sectors.

Key Features of Surya’s PE Masterbatches

Our PE Masterbatch is engineered to meet diverse industrial requirements, providing features such as:

- Excellent dispersion for uniform color and performance

- Consistent shade reproducibility across production batches

- Smooth processing behavior with improved melt flow

- High UV resistance for enhanced outdoor durability

- Good thermal stability during processing

- Improved mechanical properties such as strength and flexibility

- Optimal compatibility with PE resins

- Available in color, white, black, and additive grades

- Reduced downtime and processing defects

- Suitable for films, packaging, pipes, cables, and molded applications

These advantages make Surya Compounds & Masterbatches a trusted partner for high-performance polymer solutions.

Applications of PE Masterbatch

Our polyethylene masterbatch is widely used across industries for various plastic applications, including:

- Packaging films and bags

- Pipes and cables

- Blow-molded containers

- Injection-molded components

- Household and industrial products

Each application benefits from our customized masterbatch PE formulations, ensuring consistent results and enhanced durability.

Get in Touch

If you’re looking for a reliable polyethylene masterbatch manufacturer to enhance your product quality, contact Surya Compounds & Masterbatches today. We offer technical guidance and customized PE filler masterbatch solutions designed to optimize your production process.

FAQ

What is the main purpose of a PE Masterbatch

A PE Masterbatch is used to enhance the physical properties, color, and performance of polyethylene-based products during manufacturing.

How does a PE filler masterbatch help reduce production costs?

By replacing a portion of virgin polymer with filler material, a PE filler masterbatch maintains product strength while lowering raw material expenses.

Can PE Masterbatch be customized for specific applications?

Yes, Surya Compounds & Masterbatches provides tailored formulations for different applications like packaging, molding, and extrusion.

Is your polyethylene masterbatch suitable for food-grade applications?

Yes, we offer PE Masterbatch options that comply with food-contact safety standards and regulatory norms.

What makes Surya Compounds & Masterbatches different from other suppliers?

We ensure superior quality, technical expertise, and custom-made solutions, making us a reliable partner for all masterbatch PE requirements.