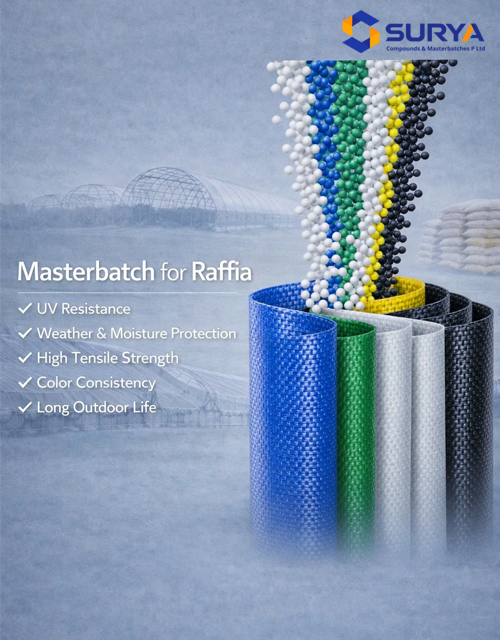

MASTERBATCH FOR RAFFIA APPLICATION

Masterbatch for raffia applications plays a critical role in enhancing the performance, appearance, and durability of PP woven tapes and fabrics. In raffia production, consistent color, high tensile strength, smooth processing, and resistance to outdoor conditions are essential. At Surya Compounds & Masterbatches, we offer a comprehensive range of masterbatches specially developed for raffia-grade polypropylene. Our portfolio includes color, white, and black masterbatches for excellent dispersion and brightness, along with UV, antioxidant, slip & anti-block, antistatic, and filler masterbatches.

These solutions help manufacturers achieve improved tape quality, reduced breakage, better weaving efficiency, and long-lasting woven products for packaging, FIBC, agriculture, and industrial applications.

Below is a detailed list of the masterbatches we produce for Raffia (PP woven) applications, designed to enhance tape extrusion, weaving performance, and end-use durability:

1. Color Masterbatches:

Formulated with high-quality pigments for excellent dispersion, strong color strength, and uniform shade consistency in PP raffia tapes and fabrics.

2. White Masterbatches:

High TiO₂ content ensures superior whiteness, brightness, and opacity, delivering clean and attractive woven sacks and fabrics.

3. Black Masterbatches:

Provide deep black color with excellent UV protection, improved weather resistance, and enhanced strength for outdoor raffia products.

4. UV Stabilizer Masterbatches:

Protect PP raffia from sunlight degradation, preventing brittleness, color fading, and loss of tensile strength during outdoor exposure.

5. Filler Masterbatches

Support cost optimization, stiffness control, and improved tape processability while maintaining mechanical properties.

Key Features of Surya’s Raffia Masterbatches

- Excellent dispersion for uniform color and additive performance

- High compatibility with raffia-grade polypropylene

- Improved tape strength and reduced breakage

- Superior UV and weather resistance for outdoor applications

- Thermal stability during high-speed tape extrusion

- Smooth processing with improved weaving efficiency

- Consistent quality for mono- and multi-tape production

- Customizable formulations to meet specific customer requirements

Applications of Raffia Masterbatch

Raffia-grade masterbatch is used in:

- Woven sacks for cement, rice, and grains

- PP woven bags

- Tarpaulin sheets

- FIBC jumbo bags

- PP ropes and twines

- Packaging fabrics

- Ground covers

These industries require strong products that can handle heavy loads, weather exposure, and long storage periods. Surya Compounds & Masterbatches provides stable solutions to support these demanding needs.

Choose the Right Masterbatch for Raffia

Boost your raffia product quality with high-performance masterbatch for raffia from Surya Compounds & Masterbatches. Get consistent strength, rich color, and long-lasting durability—connect with our experts today.

FAQ

What is masterbatch for raffia?

Masterbatch for raffia is a color or additive concentrate used in PP raffia tape lines. It helps improve color strength, UV stability, and tape durability during extrusion and weaving.

Why do manufacturers use masterbatch in raffia tape production?

Manufacturers use masterbatch to get strong, uniform, and long-lasting raffia tapes. It reduces breakage, improves stretching, and ensures stable color for woven sacks and fabrics.

Which products are made using raffia-grade masterbatch?

Raffia masterbatch is used for woven sacks, PP bags, tarpaulins, jumbo bags, ropes, twine, and ground covers.

Does raffia masterbatch improve UV resistance?

Yes. Raffia-grade UV masterbatch helps protect tapes from sunlight damage. It increases outdoor life and prevents fading or weakening.

How do I choose the right masterbatch for my raffia application?

Choose a masterbatch based on your tape strength, color needs, UV requirements, and machine speed. A trusted supplier like Surya Compounds & Masterbatches can guide you with custom solutions.