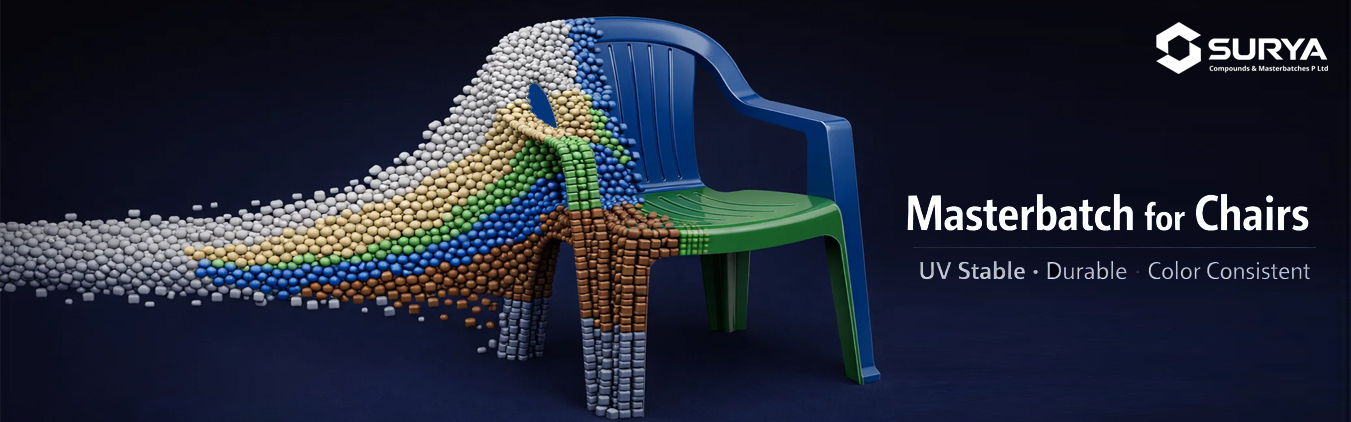

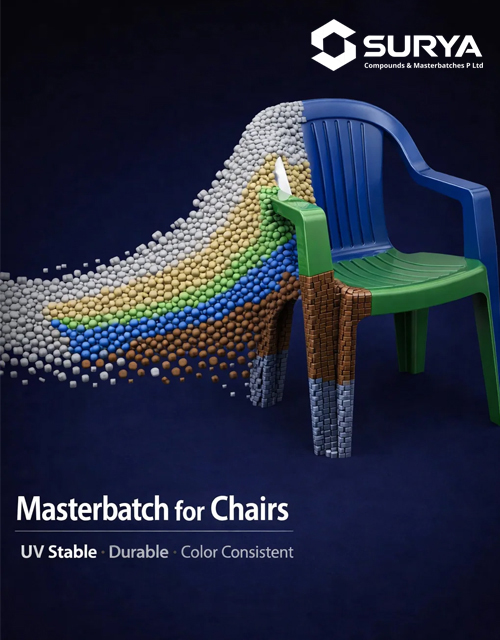

Choose high-quality masterbatch for the chair industry from Surya Compound & Masterbatches to achieve superior strength, consistent color, and smooth processing. Enhance the performance and appearance of home, outdoor, and premium chairs with confidence.

MASTERBATCH FOR FURNITURE INDUSTRY

Masterbatch for plastic furniture applications is essential to deliver an attractive appearance, high strength, and long-lasting outdoor performance. Plastic chairs, tables, crates, and molded furniture require consistent color, excellent surface finish, UV resistance, and impact strength to withstand daily use and weather exposure. At Surya Compounds & Masterbatches, we offer a specialized range of masterbatches suitable for PP, HDPE, and other polyolefins used in furniture manufacturing. Besides the regular masterbatches, we also produce special effect masterbatches, such as pearlescent, marble effect, etc., for the furniture industry.

These solutions ensure superior aesthetics, smooth molding, improved durability, and reliable performance in indoor and outdoor plastic furniture applications.

(A). Special Effect Masterbatches: Our range of special effect masterbatches includes metallic, pearl, marble, granite, wood-effect, and glitter masterbatches to create premium, designer furniture with unique visual appeal.

(B). Color Masterbatches: High-quality pigments for bright, pastel, and deep shades with excellent dispersion and long-term color stability designed specially for Furniture applications.

(C). UV Stabilizer Masterbatches: With our UV Additive Masterbatch range, protect furniture from sunlight degradation, preventing fading, cracking, and brittleness in outdoor use.

(D). Scratch-Resistant / Anti-Mar Masterbatches: Enhance surface durability and reduce visible scratches with our range of scratch-resistant additive masterbatches during daily use.

Applications of Chair Masterbatch

Chair-grade masterbatch is used in:

- Home and office chairs

- Event and banquet chairs

- Outdoor and garden chairs

- Restaurant and café seating

- Student chairs

- Premium designer chairs

- Heavy-duty industrial chairs

Each type of chair has different performance needs. Surya Compounds & Masterbatches provides solutions that match all these requirements.

Get in Touch With Us

FAQ

Why should I choose Surya Compounds & Masterbatches?

Surya Compounds & Masterbatches offers chair-grade masterbatches that give strong color, high impact strength, and a smooth finish. You get consistent quality in every batch, which helps your chairs look premium and last longer.

Does your masterbatch improve the strength of plastic chairs?

Yes. Our chair-grade masterbatch is made to improve impact resistance and surface quality. This helps your chairs stay strong even after daily use, heavy load, or outdoor exposure.

Can I get custom colors for my chair designs?

Absolutely. Surya Compounds & Masterbatches provides custom shades based on your brand style. Whether you need bold colors, soft pastels, or special tones, we match your target shade with high accuracy.

Will your masterbatch help my chairs resist sunlight and fading?

Yes. Our solutions include UV stabilizers that protect chairs from sunlight damage. This keeps your chairs bright, fresh, and durable even when used outdoors.

How does your masterbatch help in smooth injection moulding?

Our masterbatch for chair supports faster flow, better dispersion, and clean moulding. This reduces defects, saves production time, and gives you a glossy, uniform finish on every chair.Our commitment to quality, customization, and continuous innovation makes us one of the most trusted TPE masterbatch manufacturers and suppliers in the industry.