In today’s health-conscious and safety-focused world, materials that inhibit microbial growth are increasingly in demand. Antimicrobial additives for plastics and polymers are one of the most effective ways to enhance hygiene, reduce contamination, and extend the lifespan of products across multiple industries. From healthcare to packaging, antimicrobial solutions have become a crucial aspect of modern material engineering.

This article explores the types, applications, and benefits of antimicrobial additives, examines the antimicrobial additives market, and highlights the expertise of Surya Compound & Masterbatches in providing high-quality solutions for diverse polymer applications.

What Are Antimicrobial Additives for Plastics and Polymers?

Antimicrobial additives for plastics are chemical agents incorporated into polymer materials to inhibit the growth of bacteria, fungi, and other microbes. When embedded in plastics, these additives prevent surface contamination, reduce odor, and maintain material integrity over time.

Similarly, antimicrobial additives for polymers work across a range of thermoplastics, thermosets, and elastomers, offering long-lasting protection without altering the physical properties of the material.

These additives can be organic, inorganic, or metal-based, with silver ions, zinc, and copper compounds being among the most commonly used due to their proven antimicrobial efficacy.

Importance and Benefits of Antimicrobial Additives

The incorporation of antimicrobial additives into plastics and polymers provides several critical advantages:

- Prevention of Microbial Growth

They inhibit the proliferation of bacteria, fungi, and mold on surfaces, reducing the risk of infections and contamination. - Improved Hygiene and Safety

Essential in medical devices, food packaging, and consumer goods where cleanliness is paramount. - Extended Product Lifespan

Antimicrobial additives reduce microbial degradation of polymer surfaces, preserving strength and durability over time. - Reduced Odor Formation

By controlling bacterial growth, these additives help minimize unpleasant smells, especially in high-use products. - Versatile Application Across Industries

Suitable for healthcare, packaging, textiles, electronics, automotive, and more, making them highly versatile. - Compliance with Regulatory Standards

Many antimicrobial additives comply with ISO and FDA standards, ensuring safe usage in sensitive applications.

Antimicrobial Additives Market Overview

The antimicrobial additives market has witnessed rapid growth due to increasing consumer awareness of hygiene, particularly in the wake of global health concerns. Key market drivers include:

- Rising demand in medical devices and hospital equipment

- Growth in food and beverage packaging industries

- Expanding consumer goods and household products sectors

- Regulations promoting safe and hygienic materials

According to industry reports, the market is projected to expand significantly over the next decade, driven by innovations in polymer technologies and increasing emphasis on sustainability.

North America, Europe, and Asia-Pacific are the largest consumers, with Asia-Pacific—particularly India and China—showing rapid adoption due to booming healthcare, packaging, and consumer electronics industries.

Applications of Antimicrobial Additives

Antimicrobial additives applications are diverse, covering multiple sectors where hygiene and surface protection are critical.

1. Medical and Healthcare Industry

- Medical devices, surgical instruments, and hospital furniture require antimicrobial plastics to prevent healthcare-associated infections (HAIs).

- Polymer-based equipment like trays, bed rails, and IV components benefit from embedded antimicrobial agents.

2. Food Packaging

- Films, containers, and trays with antimicrobial additives extend shelf life and reduce microbial contamination.

- Helps in maintaining freshness and safety in perishable products.

3. Consumer Goods

- Household items such as kitchenware, cutting boards, storage containers, and personal care products use antimicrobial plastics for better hygiene.

- Reduces odor and surface contamination in high-touch items.

4. Automotive and Electronics

- Interiors, dashboards, and touch panels benefit from antimicrobial properties, enhancing passenger safety and reducing microbial growth in confined spaces.

- Electronics and wearable devices use antimicrobial polymers to maintain hygiene in frequently handled surfaces.

5. Textiles and Fibers

- Antimicrobial additives can be integrated into polymer fibers for textiles, creating fabrics that resist bacteria and odor—ideal for sportswear and hospital garments.

6. Water and Air Filtration

- Plastic components in filtration systems use antimicrobial additives to prevent biofilm formation, ensuring safer and cleaner air and water.

Types of Antimicrobial Additives

The effectiveness of antimicrobial additives depends on the type of agent and polymer compatibility:

- Silver-Based Additives

Widely used due to their strong antibacterial properties and long-lasting efficacy. - Zinc-Based Additives

Provide broad-spectrum antimicrobial protection and are cost-effective. - Copper-Based Additives

Effective against bacteria and viruses, often used in healthcare applications. - Organic Biocides

Include quaternary ammonium compounds and isothiazolinones, suitable for specific polymer applications. - Nanoparticle-Based Additives

Nanosilver and nanocopper offer high surface area contact, enhancing antimicrobial efficiency without affecting polymer properties.

Antimicrobial Additive Manufacturing Process

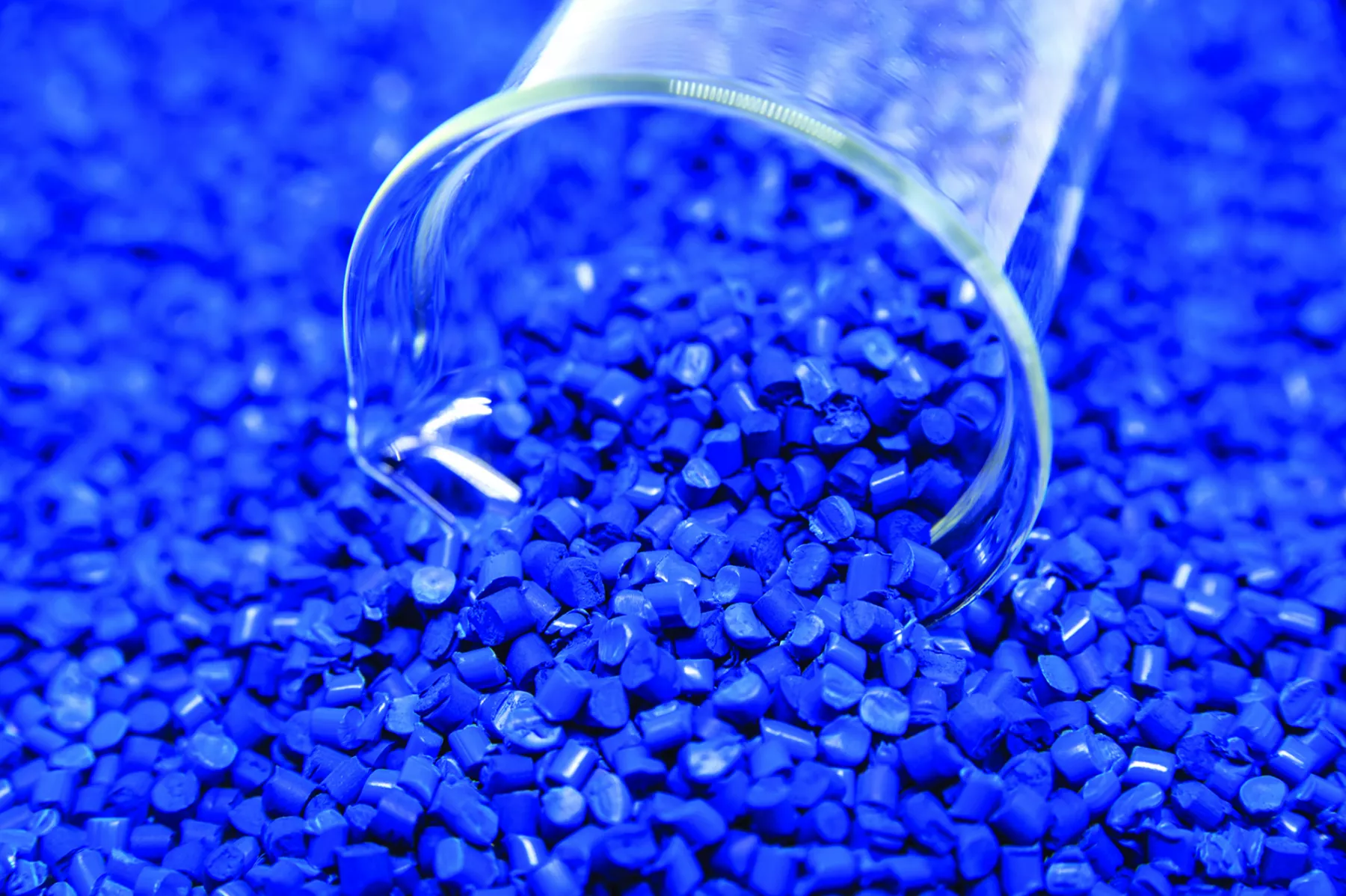

The production of antimicrobial additive masterbatches involves integrating antimicrobial agents into polymer carriers for ease of processing and uniform dispersion. The key steps include:

- Selection of Additive and Carrier Resin

Compatible polymer carriers (such as PE, PP, or ABS) are chosen to match end-use requirements. - Pre-Mixing

Antimicrobial agents are uniformly mixed with the polymer pellets before extrusion. - Extrusion

A twin-screw extruder disperses the additive evenly throughout the polymer matrix. Temperature and screw speed are optimized to prevent degradation. - Cooling and Pelletizing

The molten mixture is cooled and cut into masterbatch pellets, ready for use in downstream plastic processing. - Quality Control

Testing ensures additive concentration, dispersion uniformity, and antimicrobial efficacy meet industry standards.

Role of Surya Compound & Masterbatches

Surya Compound & Masterbatches is a trusted provider of antimicrobial additives for plastics and polymers, offering:

- Customizable masterbatch formulations

- High-quality, uniform dispersion of antimicrobial agents

- Support for multiple polymer types, including PE, PP, PET, and more

- Expertise in applications across healthcare, packaging, consumer goods, and industrial sectors

Their solutions help manufacturers achieve hygienic, durable, and high-performance products with ease of processing.

Conclusion

Antimicrobial additives for plastics and polymers are essential for modern industries seeking to enhance hygiene, prevent microbial contamination, and improve product durability. With applications spanning healthcare, packaging, consumer goods, automotive, and textiles, these additives have become indispensable in maintaining safety and quality standards.

The antimicrobial additives market continues to grow due to rising awareness, technological advancements, and regulatory support. Manufacturers rely on high-quality solutions like Surya Compound & Masterbatches for consistent performance, customization, and ease of incorporation into their polymer products.