The scientific field of materials science studies the PCL polymer as one of its most flexible and extensively researched biodegradable materials. The material has existed since the 1930s but gained popularity during the medical breakthroughs of the late 20th century. The aliphatic polyester structure of PCL creates a link between conventional plastics and materials that are suitable for biological applications. The document provides detailed information about the chemical structure, physical properties, and industrial applications of compounds and masterbatches.

1. What is Polycaprolactone Polymer (PCL)?

Polycaprolactone is a biodegradable, semi-crystalline polymer derived from the ring-opening polymerization of $\epsilon$-caprolactone. Unlike many other bioplastics (like PLA) that are derived from renewable resources like corn starch, PCL is typically synthesized from crude oil. The product obtains its “green” classification because it contains materials that break down naturally. The ester bonds in this compound will eventually break down through microbial activity, which produces water and carbon dioxide as reaction products. The material has a low melting point, which reaches temperatures slightly higher than hot tea, so it finds use in industrial prototyping and medical implant applications.

2. Chemical Structure

The chemical structure of PCL exists because of its particular molecular arrangement, which leads to its magic properties. It is composed of repeating units of hexanoate.

The Chemical Formula The repeating unit of PCL is represented as $(C_6H_{10}O_2)_n$.

Synthesis via Ring-Opening Polymerization (ROP) PCL is most commonly produced through the ROP of $\epsilon$-caprolactone using a catalyst (often stannous octoate).

- Carbon Backbone: It features a long chain of five methylene ($-CH_2-$) groups and one ester group.

- Hydrophobicity: The five $CH_2$ groups make it relatively hydrophobic compared to other biodegradable polymers, which contributes to its slow degradation rate in the body.

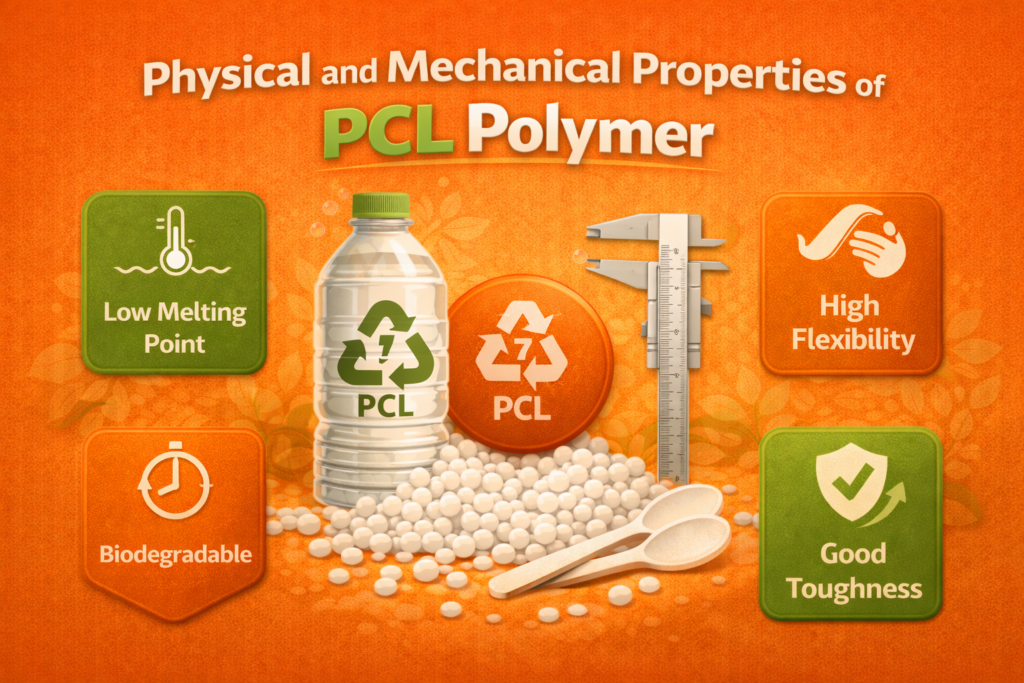

3. Physical and Mechanical Properties

PCL is known for its combination of toughness and flexibility in its material properties. It behaves somewhat like low-density polyethylene (LDPE) but with a much lower thermal threshold.

- Density: Scientists who measure density at room temperature report that PCL exists with 1.145 g/cm³ and 1.161 g/cm³ density values. The substance has a density that is higher than water, so it will sink when placed in water bodies, which needs evaluation for waste disposal and environmental effect assessments.

- Thermal Properties:

- Melting Point ($T_m$): $58-60^\circ C$ (One of the lowest for any technical polymer).

- Glass Transition Temperature ($T_g$): $-60^\circ C$.

- Because its $T_g$ is so low, PCL is always in a “rubbery” state at room temperature, which explains its high flexibility and impact resistance.

- Solubility: The chemical compound PCL shows excellent dissolution properties when exposed to the following solvents:

- Chloroform

- Dichloromethane (DCM)

- Benzene

- Toluene

- The chemical substance shows minimal ability to dissolve in alcohols and diethyl ether and petroleum ether.

4. Applications of PCL

The application profile of PCL consists of two main segments, which include high-end biomedical applications and specialized industrial manufacturing operations.

1. Biomedical Applications:

The medical field benefits from PCL because it possesses two essential properties that make it suitable for medical use. The substance PCL shows two important medical properties, which include biocompatibility and bioresorbability.

- The degradation rate of PCL exceeds that of PLA (Polylactic Acid) because it takes longer to break down.

- The material functions as a contraceptive implant or drug delivery system, which provides controlled medication release during a 1-2 year period.

- Tissue Engineering functions as a framework that enables scientists to develop new bone and cartilage tissue.

- Sutures serve as a surgical tool for particular medical procedures that need stitches that will dissolve at a controlled rate.

2. Prototyping and Hobbyist Use (InstaMorph/Polymorph)

The granular form of PCL serves as a product that hobbyists purchase. The pellets become transparent and soft like putty after being dropped into hot water, which reaches a temperature of $60^\circ C$. You can shape it through manual handling until it transforms into a rigid nylon-like plastic material during the cooling process.

3. 3D Printing

PCL is a popular filament for low-temperature 3D printing. The material maintains its shape without warping, and it sticks well to other materials, which makes it suitable for creating custom ergonomic grips and medical splints.

5. PCL in Industry: Compounds & Masterbatches

The manufacturing industry uses PCL in its pure form, known as its “neat” form, for only limited applications. The material undergoes processing to create compounds and masterbatches, which serve as additives to transform different plastic materials.

Surya Compounds & Masterbatches operate as companies that develop specific additive packages for their customers. The masterbatches in PCL serve multiple purposes for this application:

- The addition of PCL-based masterbatch to brittle polymers such as PLA results in substantial improvements to their impact resistance and flexibility.

- The company uses PCL masterbatches to develop “biodegradable blends,” which they apply for their product development process.

- Since PCL is compatible with many other resins, it can act as a bridge to improve the decomposition profile of a plastic product.

- The PCL matrix receives pigment and functional additive distribution from Masterbatches which maintains the polymer’s low-melting-point characteristics.

Important Note: The production of PCL compounds needs manufacturers to keep their processing temperature levels under complete control. The PCL loses its viscosity and turns into water when machinery temperatures reach beyond safe limits, which causes the extrusion process to stop.

6. Degradation

The process of PCL degradation leads to its natural return to the environment through hydrolysis, which breaks down its ester bonds. The compost and soil environment contains two stages which lead to this process.

- Biotic Degradation: Microorganisms (fungi and bacteria) consume the smaller fragments.

- Because of its high crystallinity and hydrophobic nature, a thick piece of PCL can take 2 to 3 years to fully degrade in a natural environment—much longer than starch-based plastics but far shorter than traditional petroleum plastics.

7. Comparison Table

The following comparison examines PCL against PLA and PHA based on their properties.

| Property | Polycaprolactone (PCL) | Polylactic Acid (PLA) |

Polyhydroxyalkanoates (PHA) |

|

Melting Point |

$60^\circ C$ | $150-170^\circ C$ | $120-180^\circ C$ |

|

Flexibility |

Very High | Low (Brittle) | Moderate |

| Degradation Rate | Slow (Months/Years) | Moderate (Industrial Compost) |

Fast (Marine/Soil) |

| Primary Source | Petroleum/Synthetic | Corn/Sugarcane |

Bacterial Fermentation |

8. Summary of Benefits and Limitations

Pros:

- Ease of Processing: Can be molded by hand or low-heat tools.

- Biocompatibility: Safe for internal medical use.

- The material shows perfect integration with other polymers, which results in better performance characteristics.

- The material maintains its ability to be reheated and remolded without any decrease in its number of uses.

Cons:

- Low Heat Resistance: Not suitable for items that will be left in a hot car or near a stove.

- The cost of this material exceeds what standard commodity plastics such as PE and PP require.

- The material remains inside medical bodies for extended periods, which does not always match the desired medical outcome.

Conclusion

Polycaprolactone functions as a distinctive material that connects different elements. It offers the structural integrity of synthetic plastics with the environmental and biological responsibility of a degradable material. The polymer kit includes this essential material because it has a low melting point and high flexibility, which enables its use in Surya Compounds & masterbatches applications for compostable bag toughening and human tissue regeneration scaffolding.