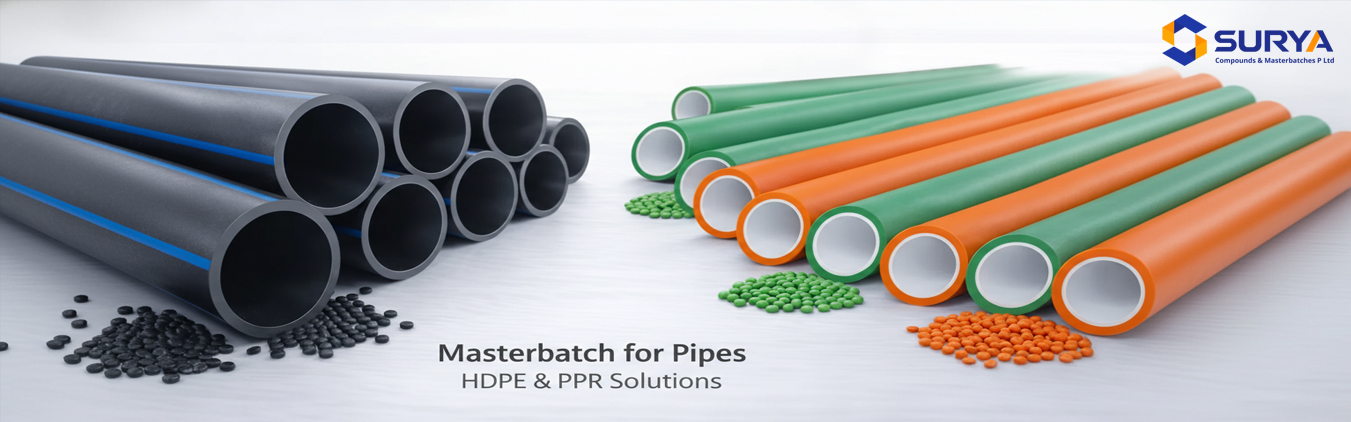

MASTERBATCH FOR PIPE INDUSTRY

Masterbatch for pipe applications is essential to ensure the strength, durability, and long-term performance of plastic piping systems. Pipes used in water supply, drainage, agriculture, and infrastructure must offer consistent color, UV resistance, thermal stability, and excellent processing behavior. At Surya Compounds & Masterbatches, we offer a comprehensive range of masterbatches suitable for PVC, HDPE, LDPE, and PP pipe applications. Our portfolio includes Color, White, and Black masterbatches, along with UV stabilizer, antioxidant, processing aid, and specialty Additive Masterbatches.

These solutions enhance extrusion stability, surface finish, and weather resistance, ensuring reliable performance and extended service life in pressure and non-pressure pipe systems.

(A). Color Masterbatches: Provide consistent and uniform coloring for pipes, enabling clear identification while maintaining excellent dispersion and heat stability.

(B). White Masterbatches: Offer high opacity and brightness, commonly used in specialty and indoor pipe applications.

(C). Black Masterbatches: Formulated with high-quality carbon black for deep color, excellent UV resistance, and enhanced outdoor durability, especially for LDPE/HDPE/PPR/PVC pipes.

(D). UV Stabilizer Masterbatches: Our range of UV Additive masterbatches helps to protect pipes from sunlight degradation, preventing cracking, fading, and loss of mechanical properties during long-term outdoor use.

(E). Antioxidant Masterbatches: Improve thermal stability during extrusion and extend the service life of pipes under continuous operating conditions.

(F). Processing Aid Masterbatches: Enhance melt flow, surface finish, and extrusion stability, enabling smoother production and reduced defects.

(G). Silicone Additive Masterbatches: Our range of silicone masterbatches helps to lubricate the inner layer of telecom duct pipes to make it easy for fiber cables to pass through.

(H). Specialty Functional Masterbatches: Include customized solutions such as anti-microbial, chemical resistance, or anti-termite masterbatches based on application needs.

Key Features of Surya’s Masterbatches for Pipe Industry

- Excellent dispersion for uniform color and additive effectiveness

- High compatibility with PVC, HDPE, LDPE, and PP-PPR polymers

- Superior UV and weather resistance for long outdoor service life

- Enhanced thermal stability during continuous pipe extrusion

- Improved surface finish and dimensional consistency

- Support for high-pressure and non-pressure pipe applications

- Smooth processing with reduced die build-up and defects

- Consistent batch-to-batch quality and reliability

- Custom-engineered formulations to meet pipe standards and end-use requirements

Applications of Pipe Masterbatch

Pipe-grade masterbatch is used in:

- Water supply pipes

- Irrigation pipes

- Agricultural pipes

- Drainage pipes

- Sewage pipes

- Electrical conduit pipes

- Industrial fluid pipes

Each application needs strong material performance. Surya Compound & Masterbatches supplies reliable masterbatch that supports these needs across various industries.

Get in Touch with Our Masterbatch Experts

Choose Surya Compound & Masterbatches for high-quality masterbatches for the pipe industry, delivering strength, color stability, and superior UV protection. Ensure smooth processing and long-lasting performance for water, drainage, and industrial pipes.

FAQ

What is masterbatch for pipe application?

Masterbatch for pipe is a color or additive concentrate used during pipe extrusion. It improves color stability, UV protection, strength, and overall performance of HDPE, PVC, and PE pipes.

How does your masterbatch improve the quality of my pipes?

Our masterbatch improves melt flow, boosts strength, and gives stable color coding. You also get better UV protection, fewer defects, and a smooth finish—helping your pipes perform better in real working conditions.

Can your masterbatch help me reduce production issues?

Yes. Surya Compounds & Masterbatches offers pipe-grade masterbatch made for high-speed extrusion. It reduces breakage, prevents streaks, and lowers processing waste, which helps you increase output and save production costs.

Can masterbatch increase UV and weather resistance for pipes?

Yes. UV stabilizer masterbatch protects pipes from sunlight damage. It increases outdoor life and prevents cracks, fading, and material weakening.

Do you offer custom colors or specific pipe shades?

Absolutely. We provide custom color matching for all pipe applications, including blue, yellow, orange, black, and other coded shades. You get accurate colors that meet industry standards and brand requirements.