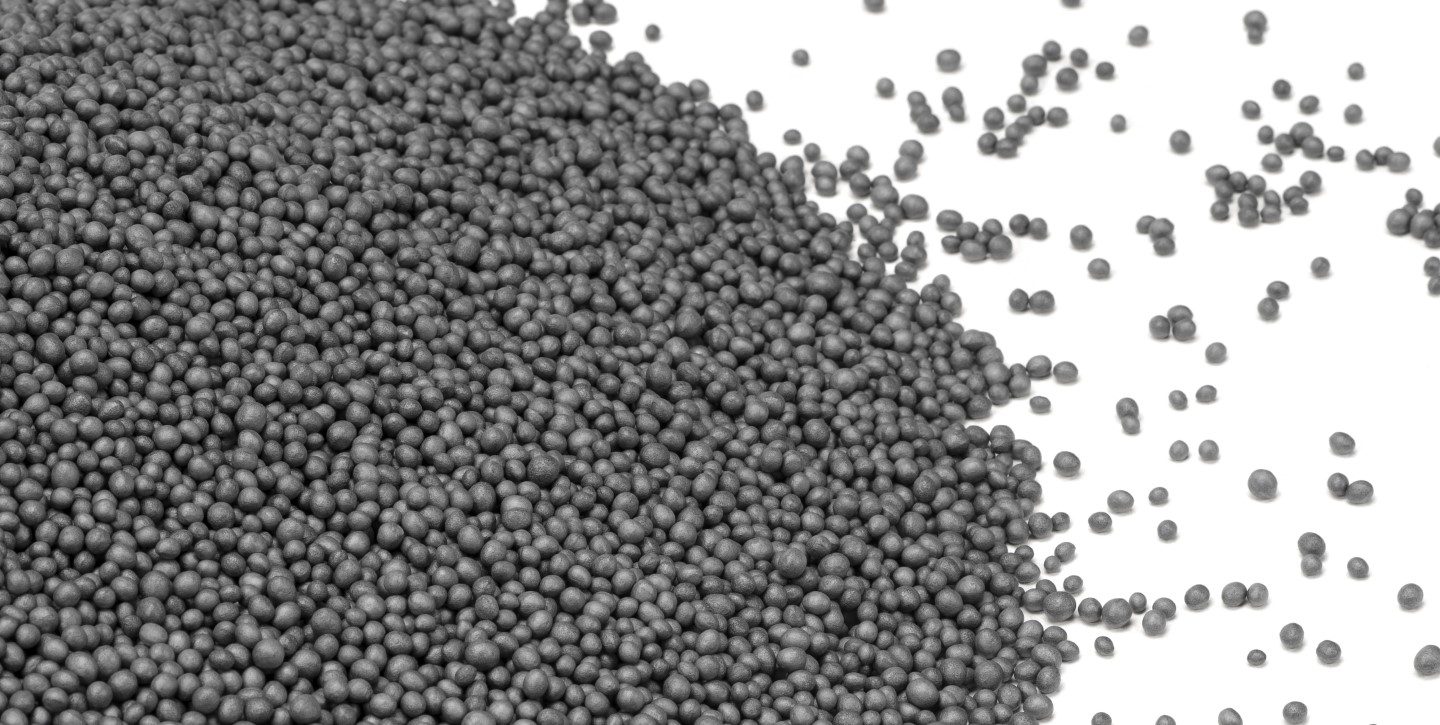

Polypropylene (PP) compounds are versatile thermoplastics derived from the base polymer polypropylene, enhanced with various additives, fillers, and reinforcements to meet specific performance requirements. These compounds are renowned for their adaptability, making them indispensable across numerous industries.

Understanding Polypropylene Compounds

A polypropylene compound is a semi-crystalline thermoplastic known for its excellent chemical resistance, low density, and good mechanical properties. By compounding PP with materials like glass fibers, minerals, elastomers, and flame retardants, manufacturers can tailor its properties to suit diverse applications.

Key Properties of PP Compounds:

- Mechanical Strength: Enhanced tensile and impact strength, especially when reinforced with fillers like glass fibers.

- Thermal Stability: Improved heat resistance, making them suitable for applications requiring thermal endurance.

- Chemical Resistance: Inherent resistance to a wide range of chemicals, including acids and bases.

- Lightweight: Low density contributes to weight reduction in end-use applications.

- Processability: Excellent moldability and compatibility with various processing techniques like injection molding and extrusion.

Applications of Polypropylene Compounds

The adaptability of PP compounds lends them to a multitude of applications across various sectors:

1. Automotive Industry

PP compounds are extensively used in automotive components due to their balance of strength, weight, and cost-effectiveness. Applications include:

- Interior Parts: Instrument panels, door trims, and consoles.

- Exterior Components: Bumpers, fender liners, and grilles.

- Under-the-Hood Applications: Battery cases, air ducts, and engine covers.

Their use contributes to vehicle weight reduction, leading to improved fuel efficiency and lower emissions.

2. Electrical and Electronics

Due to their excellent electrical insulation properties and flame retardancy, PP compounds are suitable for:

- Cable Insulation: Primary insulation for wires and cables.

- Electrical Components: Switches, connectors, and housings.

3. Packaging Industry

PP compounds are widely used in packaging owing to their clarity, strength, and barrier properties. Common applications include:

- Food Packaging: Containers, trays, and films.

- Industrial Packaging: Pails, drums, and crates.

4. Consumer Goods

The durability and aesthetic appeal of PP compounds make them ideal for:

- Household Items: Furniture, storage boxes, and kitchenware.

- Appliances: Washing machine parts, vacuum cleaner components, and air conditioner housings.

5. Medical Applications

Medical-grade PP compounds are utilized for their sterility and chemical resistance in products like:

- Disposable Syringes

- Medical Vials and Containers

- Diagnostic Devices

Common Polypropylene Products

Polypropylene compounds are transformed into a variety of products that permeate daily life and industrial applications:

- Biaxially Oriented Polypropylene (BOPP) Films: Used in packaging for snacks, confectionery, and textiles.

- Non-Woven Fabrics: Employed in hygiene products like diapers and sanitary napkins.

- Automotive Parts: Such as dashboards, door panels, and bumpers.

- Household Goods: Including storage containers, chairs, and kitchen utensils.

Leading Polypropylene Manufacturers in India

India hosts several prominent manufacturers specializing in polypropylene compounds:

1. Surya Masterbatches

Surya Masterbatches is a leading manufacturer of color, additive masterbatches, and compounds in India. Their PP compounds are known for outstanding mechanical properties and moldability, making them suitable for various applications, including automotive parts like bumper fascias, instrument panels, and door trims. They also offer PP compounds copolymerized with ethylene, providing additional toughness and flexibility. Surya Masterbatches caters to industries such as agriculture, automotive, cosmetics, electrical, footwear, medical, packaging, and more.

Company Address: Plot no. 119, Phase-IV, sec-56, HSIIDC, Kundli, Sonipat, Haryana

Contact us: +91 84700 06930

Email: info@suryamb.com

Website: https://suryamb.com/

2. Reliance Industries Limited (RIL)

RIL is one of India’s largest petrochemical companies, producing a wide range of polypropylene grades suitable for various applications. Their Hazira Manufacturing Division in Gujarat is a significant production site for polypropylene.

3. Haldia Petrochemicals Ltd

Haldia Petrochemicals manufactures polypropylene using Spheripol-II technology, producing homopolymers and copolymer grades with high consistency and excellent quality.

4. Raghav Polymers

With over 25 years of experience, Raghav Polymers specializes in the production and distribution of polypropylene, polyethylene, and polyvinyl chloride for multiple industries.

5. HMEL (HPCL-Mittal Energy Limited)

HMEL operates a world-class petrochemical complex in Bathinda, producing high and low-density polyethylene and polypropylene, catering to various application segments.

Conclusion

Polypropylene manufacturers in India have revolutionized the materials industry with their customizable properties and wide-ranging applications. From automotive components to medical devices, their versatility and cost-effectiveness make them a material of choice across sectors. India’s robust manufacturing landscape, featuring companies like Surya masterbatches, RIL, and Haldia Petrochemicals, ensures a steady supply of high-quality PP compounds to meet both domestic and international demands.